| UTIC Services Sdn. Bhd. |

| CCTV Surveys |

| Cure In Place Pipelining (CIPP) |

| High Pressure Water Jetting |

| Inflow & Infiltration (I & I) Surveys |

| Mechanical Joint Seals |

| Pipeline Radar Survey |

| Sectional Pipeline Repair |

| Utility Detection & Mapping |

| Water Leak Detection |

| Previous | |

| Next | |

| Vacancy | |

| Contact Us | |

| Staff Login |

CURE IN PLACE PIPE LINING (CIPP)

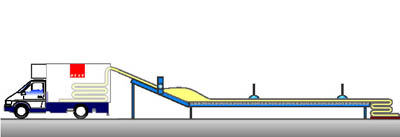

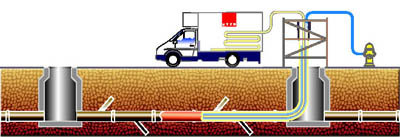

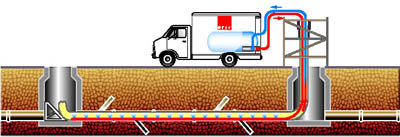

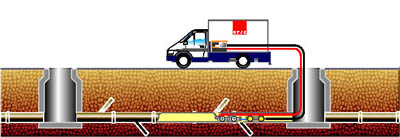

Cured in Place Pipe (CIPP) is a process of rehabilitating old and defective underground pipes without the need for read cutting and excavation works. A felt liner is impregnated with a thermosetting liquid resin that is inverted into the existing pipeline and is held in place by water pressure. Hot water is then circulated an extremely strong durable new pipe within the existing pipe. Each liner is designed to meet the specific requirement of the pipe and is capable of withstanding all leading requirements for any given situation. UTIC liners comply with all internationally recognised standards such as Water Industry Specification (WIS) 4-34-04 (WRc) and ASTM F1216 and can rehabilitate pipes ranging from 150mm to 1500mm diameter.

|

Inversion Process  Resin Mixing  Cutter Operator |